CARINI SPA

Carini gearbox Carini gears Carini geared units

The CARINI SPA company was established in 1953.

Their business employs at the moment a staff of 60 people on a 3500mq covered area (16000 mq total area) and has a high qualified technical and productive organization.

Up-to-date appliances and instruments garantee a careful check of all pieces during their manufacture as well as at their final controll.

Carini Spa carries out mainly the following:

- Design and manufacturing of gear units and spiral bevel gear units. Special designs can be developped on customer's request.

- Design and manufacture of Duplex worms and wormwheels (variable increasing pitch).

- Design and calculation tests for bevel gear sets..

- Desing and calculation tests for parallel and planetary gears.

- Manufacture on customer's request:

- Ground helical parallel gears

- Bevel gear sets (specially HPGS toothed Klingelnberg bevel gear sets )

- Wormwheels and worms

- Variable pitch wormwheels and worms (backlash recovery)

- Assembly of our units (bevel gear units, gear units, jacks) Some machinings are often carried out in team-work with other suppliers such as turning, milling, grinding and mounting.

- Carini Spa supplies important indutries specialised in different fields ( marine, land and aeronautic sectors, printing machines, tools, paper and packing...).

| MAXIMUM AND MINIMUM VALUE FOR WORKING AND COMPLETE SUPPLYING OF GEAR | |||||

|

External Straight |

|

|

External Helical Gears |

|

|

Internal Straight Gears |

|

|

Worm Wheel |

|

|

Worm |

|

|

Reishauer Grinder |

|

|

Racks |

|

|

Spline Shaft |

|

|

Bevel Gears Gleason Soiral |

|

|

Bevel Gears Gleason Straight |

|

|

Bevel Gears Gleason Hypoid |

|

|

Bevel Gears Klingelnbeg Soiral KNC 40 |

|

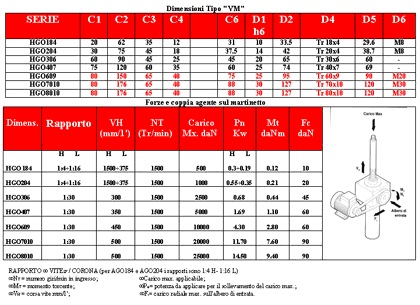

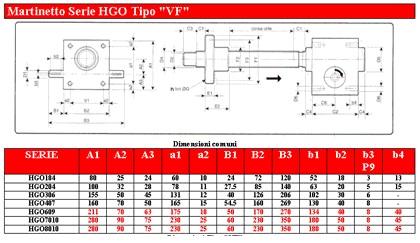

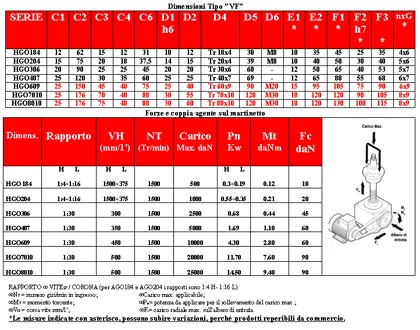

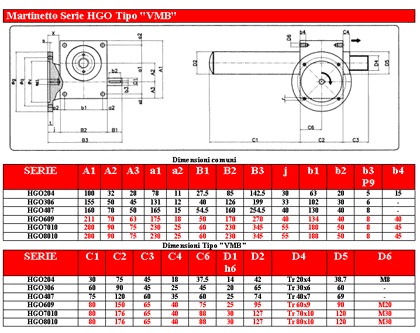

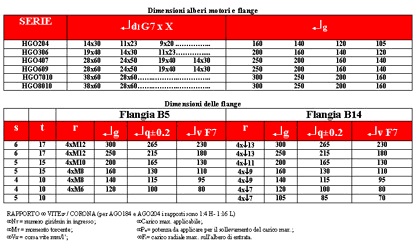

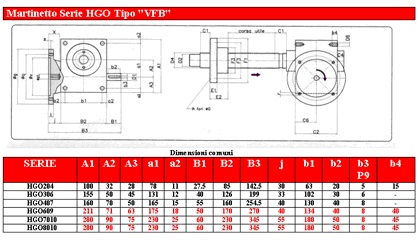

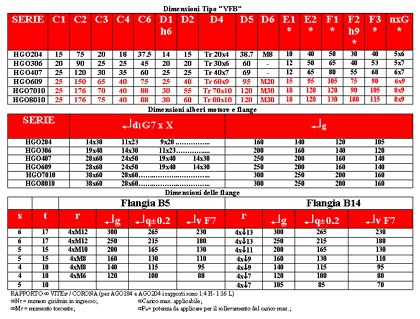

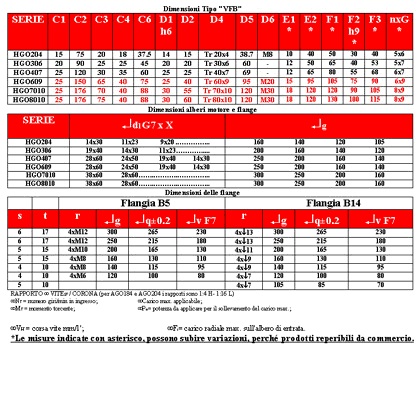

| Carini Jack Screws |

|

|

|

|

|

|

|

|

|